synchromesh manual transmission fluid

Synchromesh manual transmission fluid is a specialized lubricant designed to ensure smooth gear engagement and prevent wear in manual transmissions․ It provides optimal performance and longevity, with additives that protect against corrosion and friction․ Using the correct fluid, as recommended by your vehicle’s manufacturer, is essential for maintaining proper transmission function and preventing damage․ Popular brands like Pennzoil and Amsoil offer high-quality options for various vehicles, ensuring compatibility and reliability․

Overview of Synchromesh Manual Transmission Fluid

Synchromesh manual transmission fluid is specifically formulated to lubricate manual transmissions, ensuring smooth gear shifts and protecting components from wear․ It contains additives that prevent corrosion, reduce friction, and maintain optimal performance․ Designed for synchronizer systems, it enhances shifting precision and prevents overheating․ Proper fluid selection, as recommended by manufacturers, is crucial to avoid transmission damage and extend lifespan․

Importance of Using the Correct Fluid

Using the correct synchromesh manual transmission fluid is vital for ensuring smooth gear engagement, protecting components from wear, and maintaining optimal performance․ Incorrect fluid can lead to increased wear on gears and synchronizers, poor shifting, and potential transmission damage․ The correct fluid provides the right viscosity and additives to prevent corrosion and extend transmission life, ensuring compatibility with transmission materials and preventing leaks․ Always follow manufacturer recommendations to avoid breakdowns and maintain longevity․

What is Synchromesh Manual Transmission Fluid?

Synchromesh manual transmission fluid is a specialized lubricant designed to prevent wear and corrosion in manual transmissions․ It meets specific specifications like Mopar MS9224 and is non-weighted, ensuring compatibility with yellow metals without extreme pressure additives․

Definition and Composition

Synchromesh manual transmission fluid is a specialized lubricant designed for manual transmissions, meeting specifications like Mopar MS9224․ It is non-weighted, yellow metal safe, and lacks extreme-pressure additives․ Composed of mineral or synthetic base oils, it includes additives like friction modifiers and anti-wear agents to ensure smooth shifting, thermal stability, and corrosion protection, making it ideal for synchronizers and gear engagement․

Purpose and Function in Manual Transmissions

Synchromesh manual transmission fluid is designed to lubricate gears and synchronizers, enabling smooth shifting and preventing wear․ It reduces friction between moving parts, protects against corrosion, and ensures optimal gear engagement․ The fluid also maintains viscosity stability under varying temperatures, preventing overheating and extending transmission life․ Proper lubrication ensures efficient power transfer and minimizes the risk of mechanical failure during operation․

Key Characteristics of Synchromesh Manual Transmission Fluid

Synchromesh fluid is formulated with specialized additives for optimal lubrication, thermal stability, and wear protection․ It ensures smooth gear engagement and minimizes corrosion, while maintaining consistent performance across temperatures․

Viscosity and Performance Attributes

Synchromesh fluid’s viscosity is balanced to ensure smooth gear engagement and consistent shifting․ It maintains optimal flow in cold temperatures while providing protection at higher operating temps․ The fluid’s performance attributes include excellent thermal stability, minimizing friction, and reducing wear on synchronizers and gear teeth, ensuring reliable transmission operation across varying driving conditions and vehicle demands․

Additives and Formulations for Optimal Lubrication

Synchromesh fluid contains specialized additives like corrosion inhibitors and anti-wear agents to protect gears and synchronizers․ Formulations emphasize thermal stability, ensuring consistent performance across temperatures․ Some fluids, like Pennzoil Synchromesh, avoid extreme-pressure additives to prevent damage to yellow metals․ These additives work together to maintain smooth shifting, reduce friction, and extend transmission life, aligning with manufacturer specifications for optimal lubrication and protection․

How to Choose the Right Synchromesh Manual Transmission Fluid

Always consult your vehicle’s manual for the recommended fluid type․ Ensure compatibility with your transmission’s specifications and consider trusted brands like Pennzoil or Amsoil for optimal performance․

Factors to Consider When Selecting Fluid

When choosing synchromesh fluid, consider your vehicle’s specific transmission type, viscosity requirements, and operating conditions․ Ensure compatibility with your transmission’s material and climate․ Always refer to your vehicle’s manual for the manufacturer’s recommended specifications to avoid damage and maintain optimal performance․

Matching Fluid to Vehicle Specifications

Always consult your vehicle’s owner’s manual to identify the correct synchromesh fluid specifications․ Using the wrong fluid can damage your transmission․ Look for OEM-recommended products or equivalent alternatives․ Ensure the fluid meets the required viscosity and additive standards for your specific transmission type․ Popular brands like Pennzoil and Amsoil offer fluids tailored to various vehicle needs, ensuring proper compatibility and performance․

How to Change Synchromesh Manual Transmission Fluid

Drain the old fluid, refill with the recommended synchromesh fluid, and ensure the transmission is warm for accurate fluid level checking․ Use the correct tools for a clean process․

Step-by-Step Process for Fluid Replacement

Gather tools and materials, such as a drain pan, socket wrench, and new fluid․ Warm up the transmission by driving briefly․ Locate the drain plug, remove it to drain the old fluid, and refill with the recommended synchromesh fluid․ Replace the plug, check for leaks, and dispose of the used fluid responsibly․ Ensure the transmission operates smoothly post-replacement․

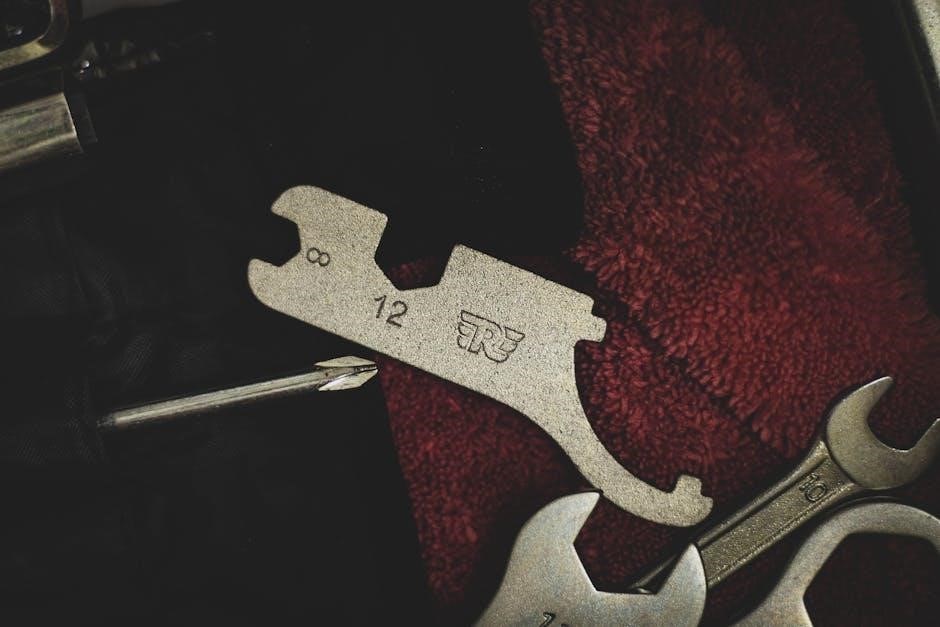

Tools and Materials Required

A drain pan, socket wrench, new synchromesh fluid, and a replacement filter are essential․ Additional items include a gasket, funnel, gloves, and safety goggles․ Ensure all materials meet the vehicle manufacturer’s specifications for compatibility and performance․ Proper tools help ensure a clean, efficient fluid replacement process and prevent contamination or damage to the transmission system․

Maintenance and Care Tips

Regular fluid checks and top-offs are vital․ Follow recommended service intervals (30,000–60,000 miles)․ Avoid using incorrect fluids and extreme temperatures to ensure optimal performance and longevity․

Best Practices for Fluid Upkeep

Regularly check fluid levels using the dipstick or side plug, ensuring it reaches the recommended mark․ Look for signs of contamination or degradation, such as dark color or particles․ Adhere to manufacturer-recommended service intervals, typically every 30,000–60,000 miles․ Warm up the transmission before draining fluid for accurate level readings․ Always refill with the correct synchromesh fluid type to maintain optimal performance and avoid damage․

Recommended Service Intervals

Typically, synchromesh manual transmission fluid should be replaced every 30,000–60,000 miles, depending on the vehicle manufacturer’s recommendations․ Check your owner’s manual for specific guidelines․ Regular fluid changes help maintain smooth shifting, prevent wear, and ensure optimal transmission performance․ Always follow the suggested intervals to avoid premature degradation of the fluid and potential damage to synchronizers and gears․

Common Mistakes to Avoid

Using incorrect fluid types, such as engine oil, can damage synchronizers and gears․ Avoid neglecting regular fluid changes and always follow manufacturer-recommended service intervals to prevent premature wear․

Incorrect Fluid Usage and Its Consequences

Using the wrong fluid, such as engine oil or incompatible gear oils, can damage synchronizers and gears, leading to costly repairs․ Incorrect fluids may not provide proper lubrication, causing friction, wear, and overheating․ This can result in rough shifting, grinding noises, or even transmission failure․ Always use the manufacturer-recommended synchromesh fluid to ensure optimal performance and avoid premature wear on critical components․

Troubleshooting Common Issues

Troubleshooting Common Issues

Common issues with synchromesh manual transmissions include rough shifting, noise, or leaks․ Check fluid levels and condition, as low or degraded fluid can cause poor performance․ Ensure the correct fluid is used, as improper substitutes can lead to malfunction․ Inspect for leaks around the transmission pan or seals․ If issues persist, consult a mechanic to avoid further damage․

Top Brands and Products

Top brands offering high-quality synchromesh manual transmission fluids include Amsoil, AC Delco, Pennzoil, and Honda MTF․ These products are known for their superior lubrication and reliability․

Popular Synchromesh Fluid Brands

Popular synchromesh fluid brands include Amsoil, AC Delco, Pennzoil, and Honda MTF․ Amsoil is renowned for its superior lubrication and compatibility with various manual transmissions․ AC Delco is a trusted choice for its OEM-quality reliability․ Pennzoil offers enhanced thermal stability, ensuring smooth gear engagement․ Honda MTF is specifically formulated for Honda vehicles, providing optimal performance and durability․

Product Reviews and Recommendations

Amsoil Synchromesh Manual Transmission Fluid is highly rated for its smooth shifting and durability․ AC Delco Synchromesh Fluid is praised for its OEM compatibility and performance․ Pennzoil Synchromesh Fluid is recommended for its excellent thermal stability and protection against wear․ Honda MTF is a top choice for Honda vehicles, ensuring optimal gear engagement․ These products are consistently reviewed as reliable and effective for manual transmissions․

Safety and Handling

Always wear protective gloves and eyewear when handling synchromesh fluid․ Work in a well-ventilated area to avoid inhaling fumes․ Avoid skin contact and wash hands thoroughly after use․ Ensure proper disposal by placing used fluid in sealed containers and following local regulations to prevent environmental contamination․

Precautions for Handling Transmission Fluid

Always wear protective gloves, goggles, and work in a well-ventilated area to avoid inhaling fumes․ Avoid direct skin contact with the fluid, as it may cause irritation․ In case of skin contact, wash thoroughly with soap and water․ Keep the fluid away from open flames or sparks, as it is combustible․ Properly dispose of used fluid and containers according to local regulations to prevent environmental contamination․ If swallowed, seek medical attention immediately․

Proper Disposal Methods

Dispose of used synchromesh manual transmission fluid responsibly by taking it to a certified recycling center or auto parts store that accepts used fluids․ Never pour it down drains or mix it with household waste․ Use a sealed, leak-proof container to transport the fluid․ Always check local regulations for specific disposal guidelines to ensure environmental protection and compliance with waste management laws․

Synchromesh manual transmission fluid is a crucial component for smooth gear operation and longevity․ Using the correct fluid ensures optimal performance and protection․ Always follow manufacturer guidelines for best results and to maintain your vehicle’s health․

Synchromesh manual transmission fluid is essential for smooth gear engagement and transmission longevity․ Proper fluid selection, as per manufacturer guidelines, ensures optimal performance and protection․ High-quality fluids, like Pennzoil Synchromesh, offer enhanced lubrication and corrosion resistance․ Regular maintenance and correct fluid replacement are critical to prevent damage and extend transmission life․ Always prioritize OEM recommendations for compatibility and reliability․

Final Thoughts on Synchromesh Manual Transmission Fluid

Using the correct synchromesh manual transmission fluid is crucial for optimal performance and longevity․ High-quality fluids, like Pennzoil Synchromesh, ensure smooth shifting and protect against wear․ Regular maintenance and adherence to manufacturer recommendations are essential to avoid damage․ Investing in the right fluid and following proper care guidelines will extend your transmission’s life and reliability, making it a worthwhile priority for any vehicle owner․